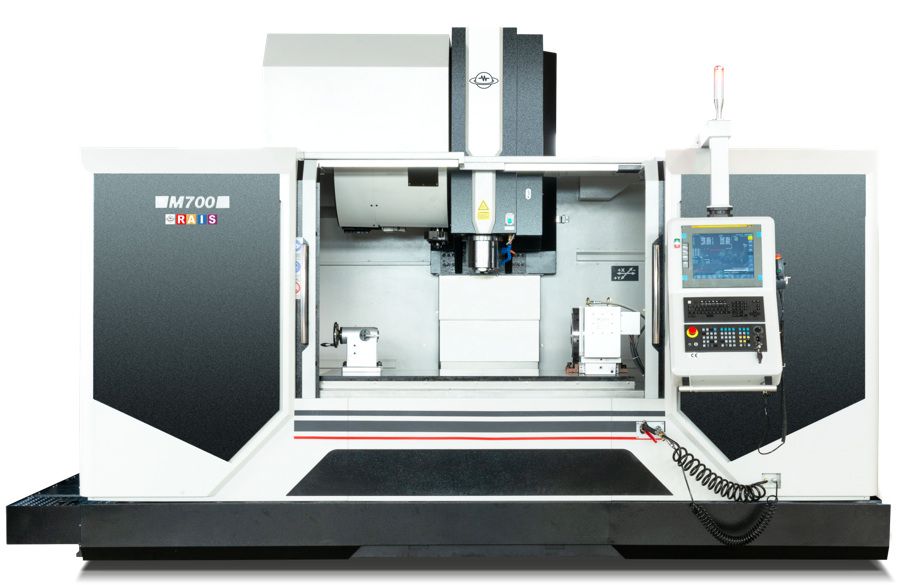

These vertical machining centers are designed to perform various machining operations on medium and large-size work pieces in high cutting speed and feed conditions.

Reinforced spindle assembly with precise grinded parts. Increased size of bearings. High processing speeds under heavy operating conditions.

Telescopic guards along the three axes: long life of the ball screws and the linear guide ways; fast and efficient flushing of chips by means of coolant liquid.

24 ATC fast tool change magazine - 2.8 sec. Automated air blow during tool change.

Fully enclosed machine guarding design provides a save, dry, clean working environment. Swivel panel of the CNC control. Highest convenience for easy setup and manipulating.

Wide and hardened precise grinded flat slide ways on all axes. Stable work by heavy cutting conditions. Super high grade “Turcite- B” fitted to X, Y, Z slide ways gives 40 % greater stability.

All ball screws - high precision, class Р3, Ø40 mm OD, with a double nut, pre-loaded to control backlash. High precision of positioning and smooth operation.

Directly coupled to the ball screws AC servo motors along all axes. Excellent interpolation accuracy.

Guaranteed precision and stability in the long transverse stroke of the four flat guideways surfaces on Y-axis.

Dialog Programming, accordingly Manual Guide / ShopMill